Our Products

Kinetix specializes in targeted, high-impact modifications for NCR Power Enterprise and/or NCR Power Warehouse that solve real-world challenges in food distribution. Our products are designed to enhance efficiency, accuracy, and overall operations for distributors using NCR Power software.

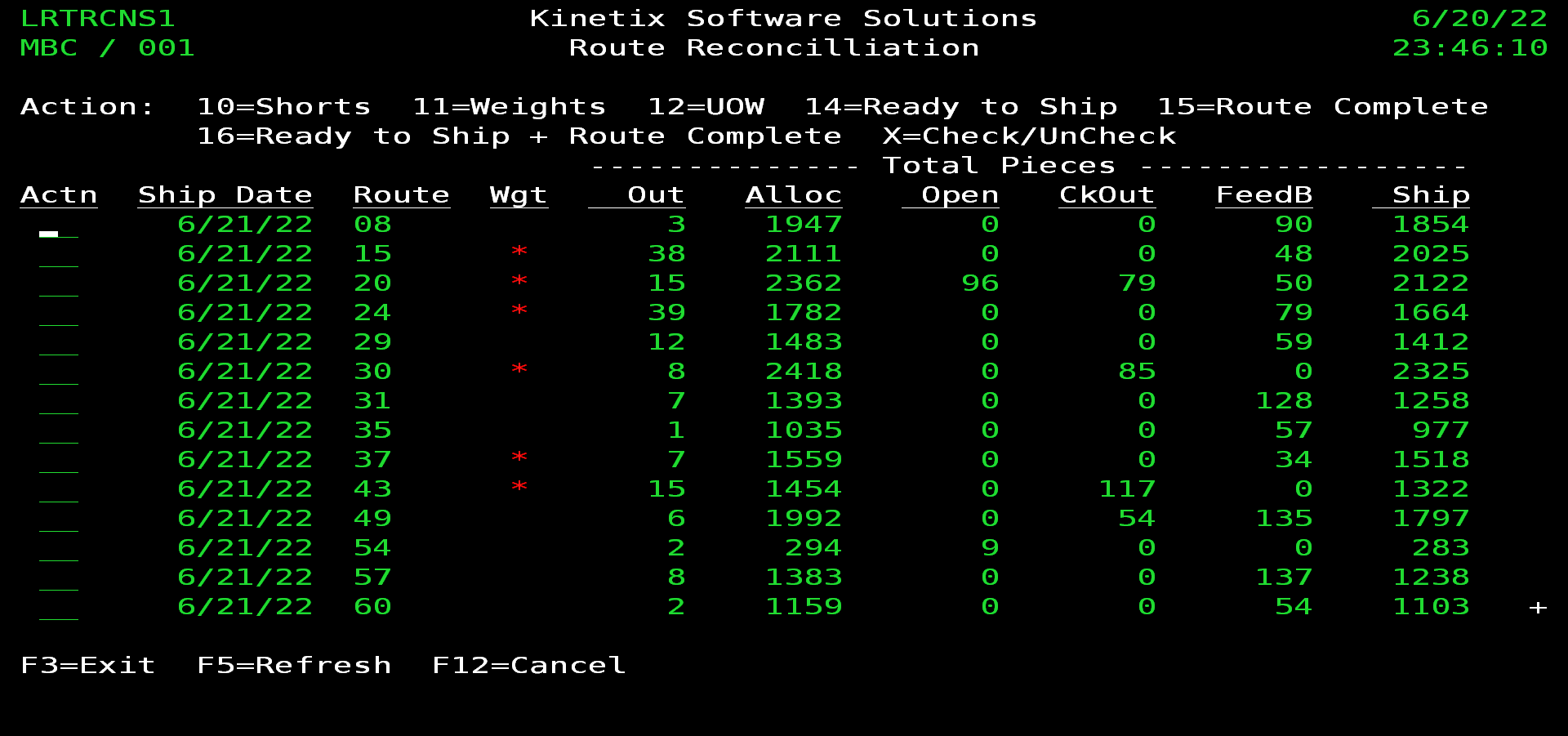

If you are having problems reconciling shorts and weights in NCR Power Warehouse before invoicing, Route Reconciliation might be exactly what you need. It integrates directly with the Route Processing screen.

Key Features:

Testimonials:

"We have been using route reconciliation for about two years. It has been wonderful. It has dramatically cut the night shift's time in processing the orders. Instead of having to go to each screen to do different functions, like feedback, they are all in route reconciliation, so you never need to leave that screen. They can see and process everything they need to do from shorts, catch weights, receiving info, closing units of work, variances, adjustments, and reporting.Carolyn Abouelhana, Hillcrest Food Service, Cleveland, OH

The night crew has been very happy, and it has cut errors because the software warns them on the catch weights. They have checks to make sure nothing was missed. We love this product and will always use it."

"We have recently started using the route reconciliation. The first thing that got our attention was the fact that our team can remain on one screen and not have our processors flipping back and forth through multiple screens. While on this screen we are easily able to catch incorrect weights, correct the weights, short/add items, close units of work, complete feedback and process routes.Flo Richter, Mason Brothers Company, Wadena, MN

We have had 2 different shifts using this and from both shifts we have received positive feedback on the ease of learning and use.

We would recommend route reconciliation to anyone looking to reduce errors and save time!"

Print pallet labels only when needed by scanning the barcode during receiving – eliminates pre-printing waste and errors.

Benefits (from client feedback):

- Saves time and money on labels/ribbon.

- Increases receiving speed by 20-50%.

- Reduces errors from wrong labels or multiple prints.

- Allows multiple clerks on one PO without duplicate labels.

Hillcrest Food Service

"We are very pleased with the receiving labels on demand. Not only has the company saved money but the users are very happy with it. This has saved them so much time. One of the biggest loads we receive is 400 items and they used to have to fumble around in the labels looking for the correct label for that item. Now, they just scan the bar code and the label is there. Also, we have different warehouses and sometimes the user would print the labels in both facilities. This is very costly with the labels. Now, we do not have to worry about that. They have the printer with them and will only send the labels once. We estimate that we will also save close to $500 annually on labels and ribbon, over and above the money saved in increased receiver productivity. Also, the implementation was very easy. This took about an hour to set up the printers and testing took another hour. This has been one of the best changes that our company has done and we would recommend this for every food distributor."Carolyn Abouelhana, Hillcrest Food Service, Cleveland, OH

Imperial Trading Company

"There are several ways that we save by using on demand pallet labels.

- Eliminates printing pallet labels on prior day.

- Reduction in personnel who prints and folds all labels the previous day or even the day of receiving.

- Increase speed of receiving by as much as 50% on smaller purchase orders and up to 20% or more on large purchase orders.

- Eliminates flipping through 1-100+ lines on a stack of preprinted pallet labels.

- Can have multiple clerks receive a P.O. and not have to print 2 sets of pallet labels.

- Accuracy is increased as clerks will have to scan UPCs rather than finding work-arounds. (keying in item # or scanning the item # bar code on the pallet label)

- Eliminates opportunity for clerk to use the wrong pallet label. (Can possibly cause errors and confusion later by inventory and replenishers as preprinted info does not match item assigned to that pallet number.

- Reduction in the number of labels used as we are only using labels that we receive and don’t waste time on reprints for various reasons as well as size change from 4"x6" to 4"x4"."

Richard Duhon, Imperial Trading Company, New Orleans, LA